From the products that drive our everyday life and increase our productivity to the military systems that are critical to national defense, microelectronics are the technological tap root of the most advanced tools and systems upon which we depend. Every year in every innovation, our dependency deepens, resting on a global supply chain system that is fragile. The pandemic drove home the point.

From the products that drive our everyday life and increase our productivity to the military systems that are critical to national defense, microelectronics are the technological tap root of the most advanced tools and systems upon which we depend. Every year in every innovation, our dependency deepens, resting on a global supply chain system that is fragile. The pandemic drove home the point.

So, in the past two years, American leadership in government and business have embraced the need to re-establish the industry’s domestic semiconductor manufacturing capacity, and both private and public investment (the CHIPS and Science Act) have driven a reawakening. Activity is intensifying at all levels and Arizona is in the thick of it.

An historical home to microelectronics companies, Greater Phoenix is now a hub of this phase of domestic reinvestment in the industry. Intel and Taiwan-based TSMC (the largest semiconductor manufacturing company in the world) lead the way, but they are not alone and companies of all sizes feed the supply chain.

As industry and government investments advance innovation and expansion in microelectronics, American universities have an important role to play.

Arizona State University, home to the largest engineering school in the country now with more than 30,000 students, sits at the center of this activity. Our faculty and students work closely with companies in the Valley — from Intel and TSMC to startups and mid-sized companies, through internships, fellowships, applied learning programs and research projects. ASU produces graduates in demand and ready to enter the industry. ASU also works with companies and employees already in the industry through short courses and certificate programs that enable people to sharpen their skills or acquire new skills that both advance their career and provide the workforce that these growing companies need.

For the past eight years, ASU has been ranked No. 1 in innovation by US News & World Report — a designation that invites the question, “What exactly does that mean?” It is a mindset that flows from the ASU charter, an institution designed as a national service university, built to accelerate positive outcomes through the integration of cutting-edge technological innovation. And it means that ASU is responsive in moments like this that call upon us to work collaboratively to pursue goals in the vital interest of our country.

Some examples:

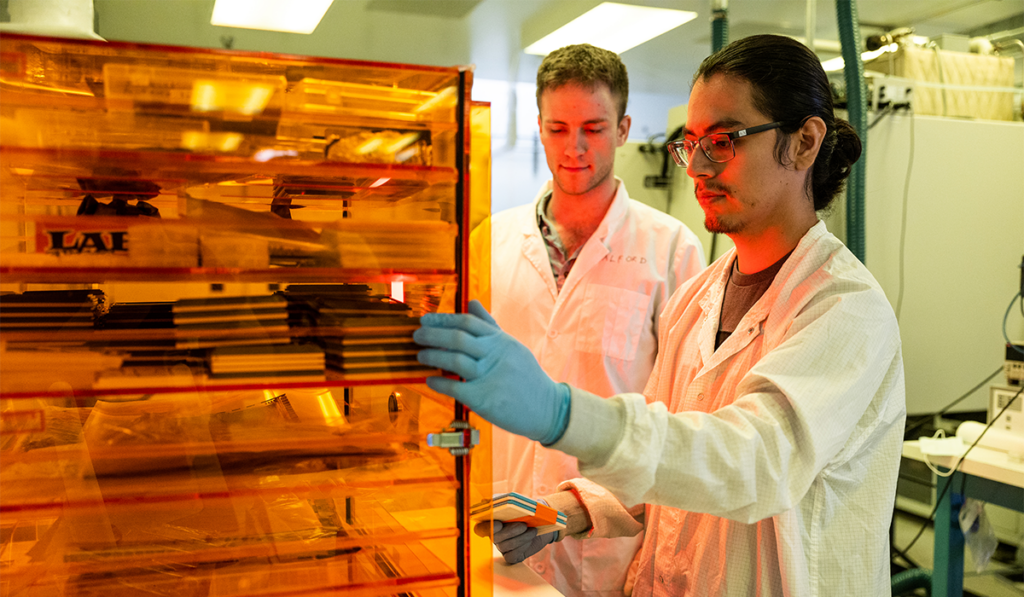

ASU’s MacroTechnology Works – This one-of-a-kind hybrid facility, both a lab and a fab, advances research and development, and manufacturing — bridging a gap that enables companies to prototype at scale and push new concepts from development to commercialization and adoption. Companies from around the region utilize this facility because it provides such a unique setting for collaboration with faculty and students.

Dreamscape Learn – Given the demands of workforce development, ASU is working creatively to develop new ways to access learning and deliver student success. Dreamscape Learn is a collaborative venture between Dreamscape Immersive and ASU, merging the most advanced pedagogy with the entertainment industry’s best emotional storytelling, redefining how we teach and learn in the 21st century.

Meeting the moment with government and industry – ASU is well on its way to creating a world-class center of excellence for microelectronics research, development, education and training, and works closely with government agencies such as Defense and Commerce to meet the objectives of the CHIPS and Science Act.

Summoning the will to become a global leader in microelectronics is one thing; developing the workforce is another.

Producing people with the skills capable of driving a rapidly changing industry at the scale necessary to meet the country’s goal of developing the biggest and best semiconductor manufacturing ecosystem in the world will take time, effort and collaboration. America’s universities have a critical role to play.

Jay Thorne is assistant vice president of Media Relations & Strategic Communications at Arizona State University.

Did You Know: ASU’s MacroTechnology Works and the tools it houses are an order of magnitude larger than the clean room and nanofabrication facilities at other universities. MTW’s scale makes it a bridge across the so-called “Valley of Death” that exists between facilities and expertise and is a frequent barrier to tech transfer.